Our major skill

V.I.P. has a machine park of 14 entirely automated injection presses, ranging from 70 to 200 tons; four of them are high pace presses (packaging).

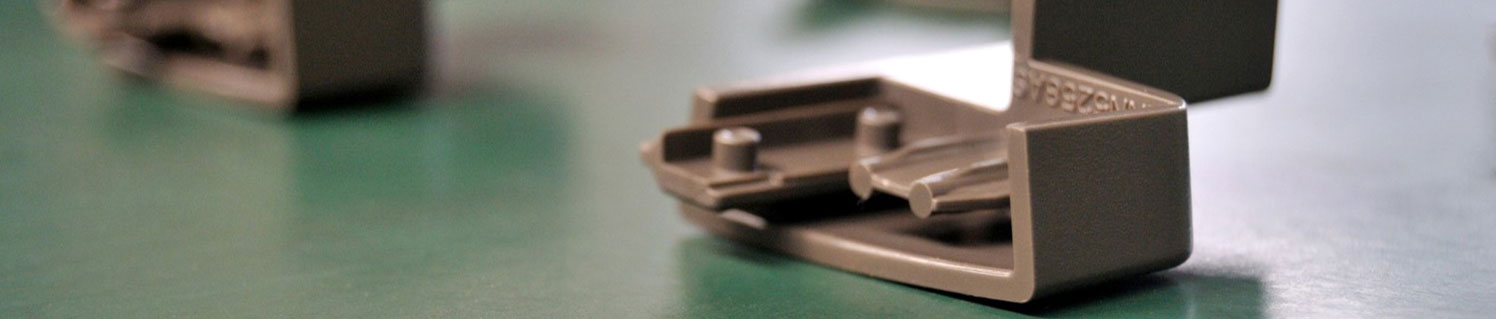

This allows us to manufacture parts for all industrial fields, such as: sunshade flaps, engine connections, rolling shutter nozzles, glazing blocks for constructions, round and square bowls, domestic funnels, agri-food jars, electrical connections, etc.